Business & Education

The Dane who drove Detroit to success

This article is more than 9 years old.

Look up William Knudsen in Encyclopaedia Britannica and you’ll fund out he was an ‘American industrialist’, but one of the most important figures in the early history of the auto industry was a Dane

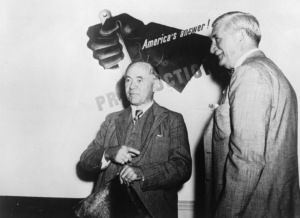

Knudsen (right) with Lord Beaverbrook – part of the Churchill Coalition Government – in 1945 (photo: Imperial War Museums)

Voldmestergade Street number 26 in the Kartoffelrækkerne neighbourhood probably doesn’t make it on to many lists of Copenhagen tourist attractions these days. But in the years after the Second World War, there was a constant stream of Americans making a pilgrimage to the boyhood home of the man who made GM and who eventually rose to become the second most important person in the US war effort after FDR.

William S Knudsen – or ‘Big’ Bill Nudsen, as he came to be known in his adopted America – was actually born Signius Vilhelm Poul Knudsen. One of six children born to the cooper and his wife who lived in the Copenhagen flat, he showed his talent for mechanics at an early age by building the city’s first tandem bicycle. It would turn out though, that what would propel his career was not two-wheeled transport, but the automobile.

Knudsen emigrated to America in 1900 at the age of 21. And the story of his first years there is typical of the successful immigrant: $30 to his name; started working in sweeping up job, improved his English at night by listening to the landlady’s children, took engineering correspondence courses to move ahead in the world.

Finding his Ford

But, if Knudsen’s start was typical, the rest was anything but. His own, oft-repeated, account of his introduction to his adopted country – and one that would serve as his mantra throughout his career – was that as he made his way down the gangway, marvelling at New York’s wonders, a deckhand bumped him from behind and yelled: “Hurry up, you son of a bitch!”. Knudsen always completed the tale: ‘And I’ve been hurrying ever since.’

And while it was his experience making bicycles that helped him land a job in 1902 at the John R. Keim Mills, a bicycle factory which was branching into automobile parts. It was his never-slow-down attitude that helped him advance: four years later he was assistant manager. The next year, in 1906, he was manager.

Ford became the first major customer for the factory’s car parts, and in 1911 it bought the factory. Knudsen, now a Ford employee, was ordered to set up a new auto parts factory – a task he repeated 14 times in the next four years.

Reaching for the Starliner

By the time the first First World War was over, Knudsen had nearly reached the peak of the American corporate ladder. The company’s production manager during its great expansion period which saw it expand to a workforce of 80,000 to build the Model T, Knudsen played a key role in creating modern mass production.

His successes helped him become the right-hand man to Henry Ford, and his influence on the company’s founder extended to convincing Ford to choose Denmark as the site of its first foreign factory in 1919 on Heimdalsgade Street in Copenhagen. Nevertheless, Knudsen fell out with Ford in 1921 during a labour dispute and was quickly snatched up by General Motors.

The firing proved to GM’s gain. In 1924 became the company’s vice-president in charge of the new Chevrolet brand, which he came to challenge the dominance Ford’s Model T. His foresight into the needs of the American led General Motors to focus production on powerful six-cylinder engines that powered the company’s most popular models.

WWII wonders

When a new job was created for him in 1933, as executive vice president in charge of all GM operations, Knudsen had unquestionably made his the biggest automobile operations job in the world. Knudsen reached the pinnacle of his auto career in 1937 when he was named to president of General Motors and its 230,000 employees.

It was no surprise, then, that when President Franklin Delano Roosevelt, in 1940, sought someone to head the US militarisation effort, he went to the man who was producing more cars than anyone else in the world at that time.

The statistics show Kundsen’s worth to the militarisation: in 1939, no tanks were produced in the US. By 1943, 40,000 a year were rolling into action; 10,000 tonne ships were being built in four days; and he was the brains behind the jeep and the bulldozer.

Knudsen, who at GM was the second highest paid man in America, was paid a salary of $1 a day for the position that put him in charge of 11 million people – three times the number of people living in Denmark.